Why Amity Rugged?

We always deliver our rugged computers with the quality assured and quick rundown.

Make in India

Rapid Response

Compliance Testing

5 Years Warranty

Short Lead Time

Technical Support

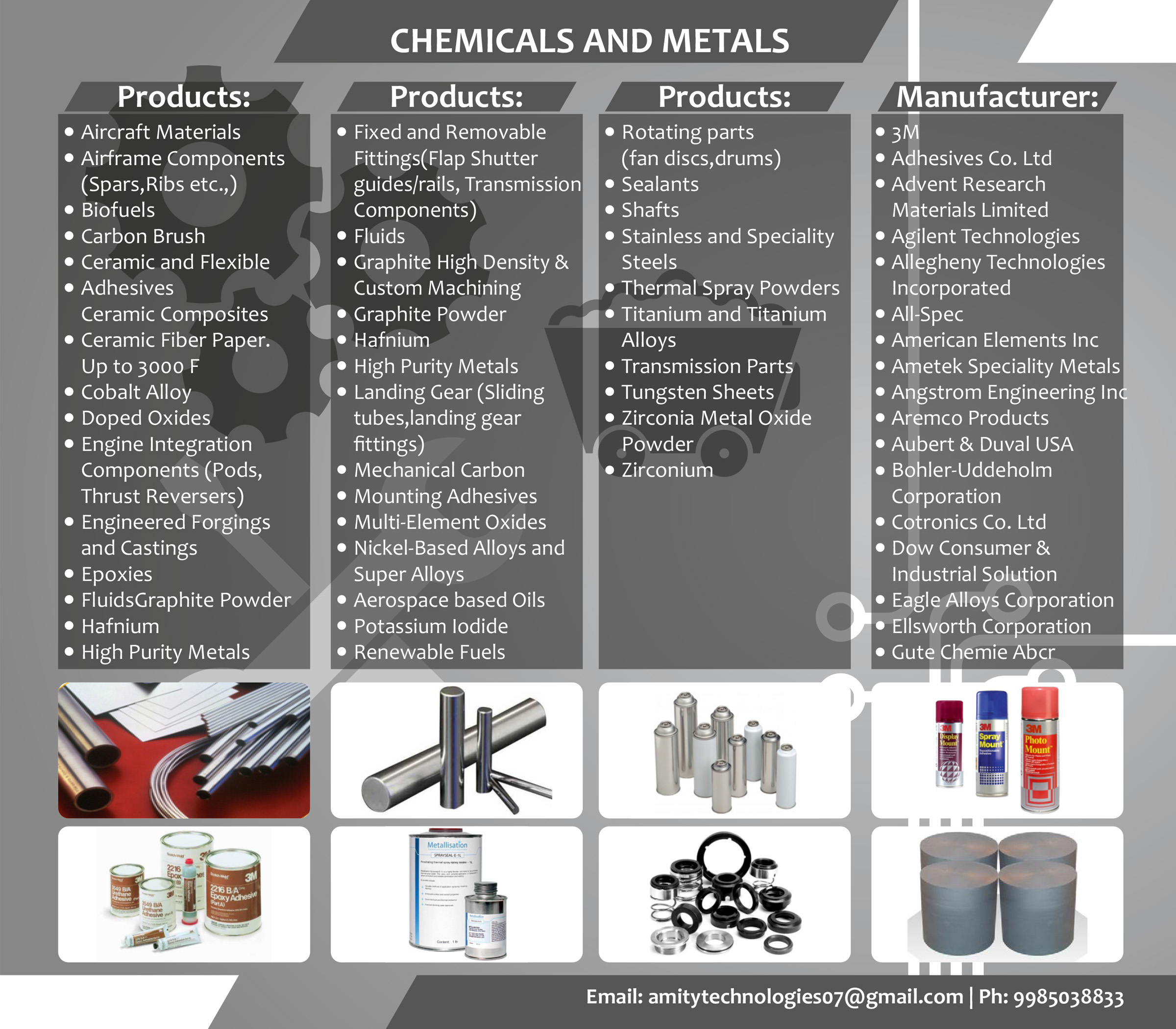

10 STEP MANAGEMENT

ELECTRO-MECHANICAL PACKING DESIGN AND VERIFICATION PROCESS

Amity Team is the culmination of years of experience and in-depth working knowledge of electrical and mechanical design. Our rugged chassis designs are the result of vast customer and application experience. Our engineers work closely with the customer to bring the desired system to reality using the following processes:

- Full FEA / Thermal Simulations

- Inventor 3D Modeling for All Designs

- Component Compatibility Verification for the Intended Application

- Shock and Vibration Testing for Design Qualification

- Design Qualification Over Extended Temperature

- Use of Locked BOMs and Revision Controls

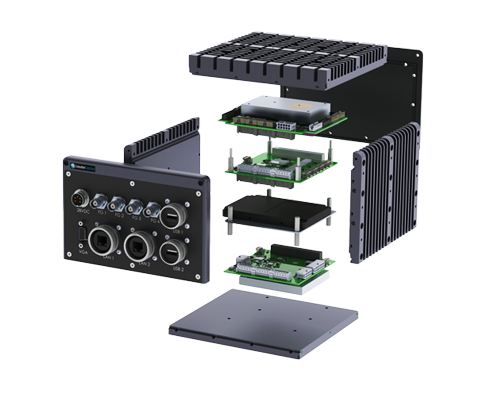

SHOCK MOUNTING OF STORAGE ARRAYS

All drives, passive backplanes, and some motherboards are shock mounted to the chassis. Proper shock mounting of critical components is necessary to survive harsh environments.

CABLE TIE DOWNS

Amity engineering and production pays particular attention to the routing of cables within the chassis for effective air flow considerations. We also make extensive use of dedicated cable tie downs (bridges) in our designs to ensure adequate strain relief and to eliminate cable pinching.

HOLD DOWN BARS & CLAMPS

All add-in boards and some memory modules are secured through the use of hold down bars and clamps. Clamps utilize specially designed grommets for proper stabilization of boards as well as the memory modules. When necessary, we employ dual hold down bars to allow securing of full-length boards and provide a secondary role as chassis stiffeners.

COOLING & VENTILATION DESIGN

All Amity designs incorporate advanced thermal technology. Temperature testing is performed at 50° C for a minimum of 24 hours with a maximum load as part of the qualification process. All Amity systems are designed and built to allow for maximum air flow, ensuring continuous operation at wide temperature ranges.

ELECTRONICS & CABLE RTV PROCESS

Amity makes extensive use of RTV (Room Temperature Vulcanizing) for securing cables that are not locked down. This process is also used for certain electronic components on PC boards to ensure operation under demanding shock and vibration conditions.

BURN IN PROCESS

Prior to final test, all Amity computers go through a 24-hour computer controlled burn in period at 50° C with full diagnostics to identify and eliminate infant mortality. For certain applications, the burn-in process is extended to 48-72 hours.

SHIPMENT PACKING DESIGN

Amity designs its own boxes and packaging inserts to ensure reliable shipments of its products world-wide.

PREMIER TRANSPORT SERVICES

Amity chooses and ensures best transport services for the shipment of its products world-wide.

SUPPLY CHAIN MANAGEMENT SERVICES

Amity has a robust program for counterfeit risk mitigation and EOL management of parts. From sourcing long life components to last time buys, Amity can provide a custom solution for your application.